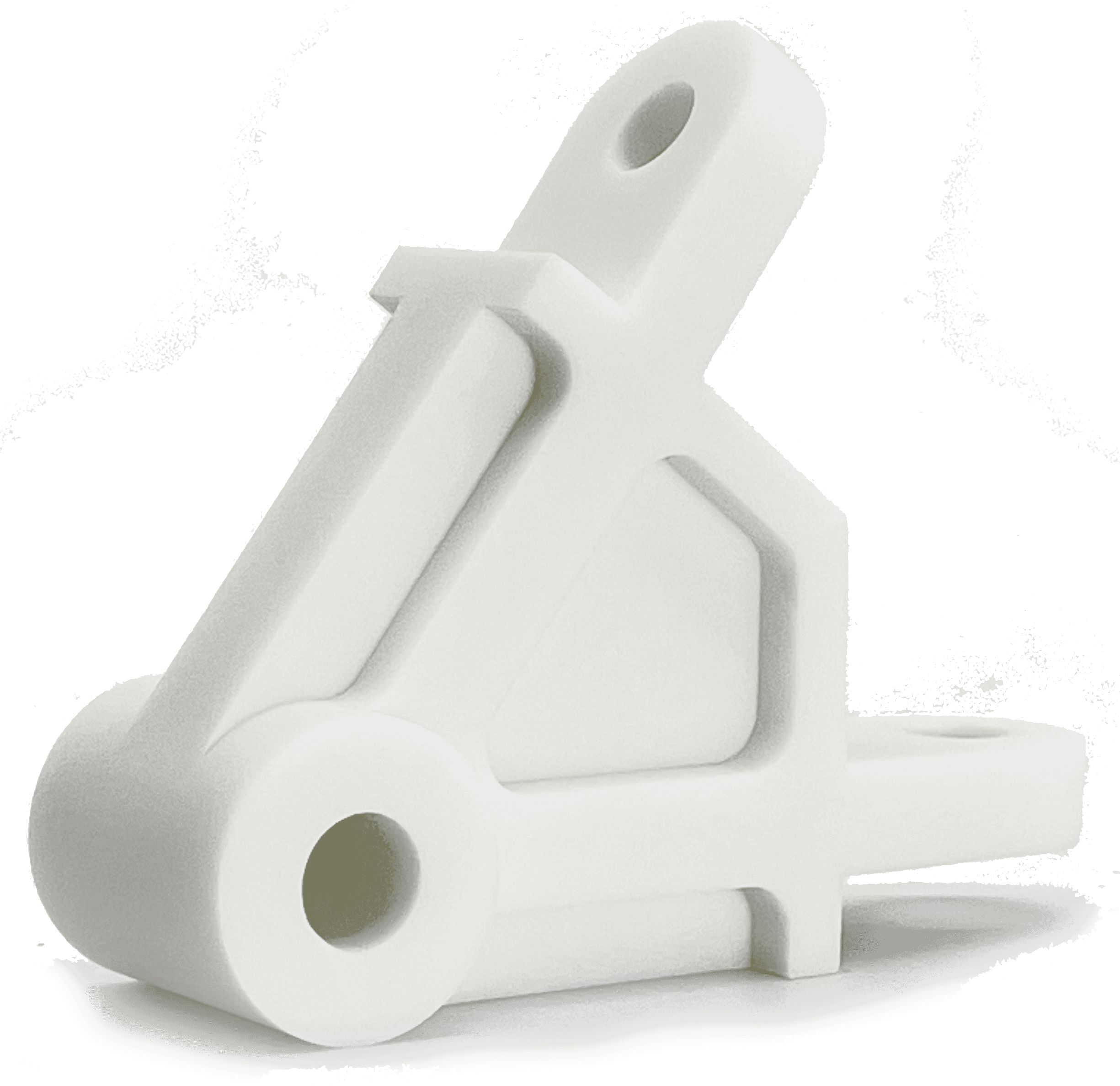

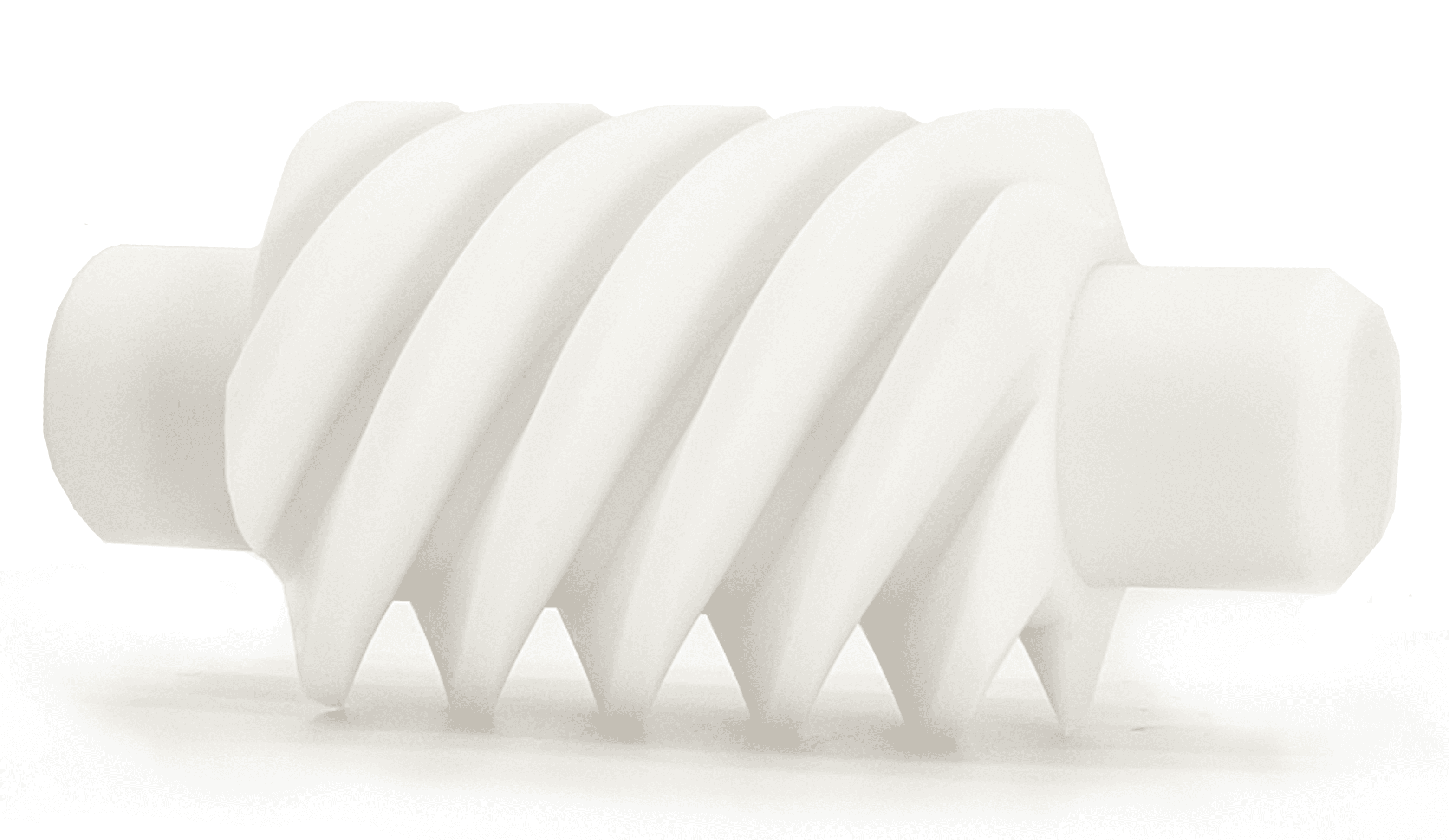

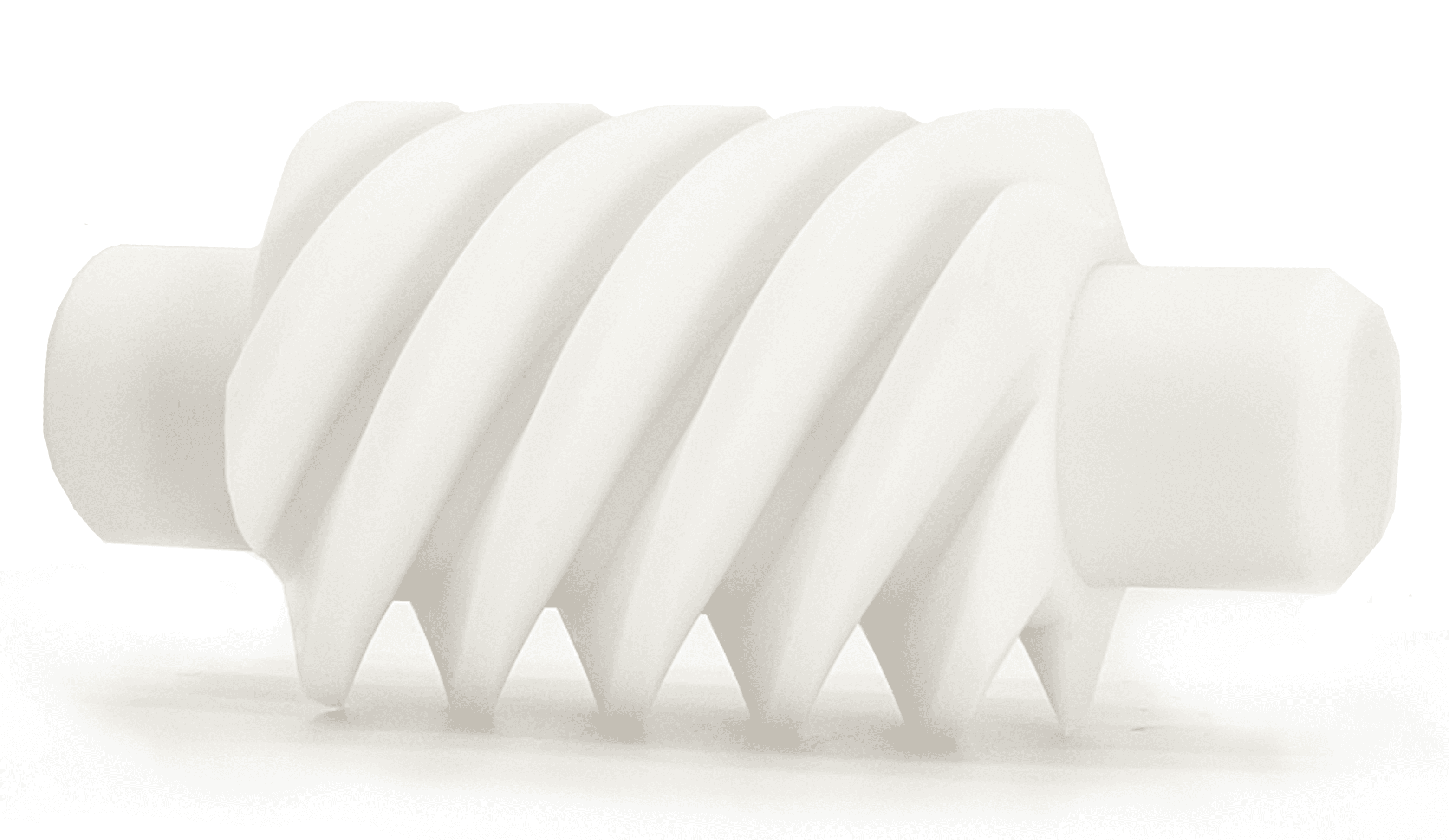

Rigid 4000

Technology:

The Rigid 4000 resin has absolutely no flex. It's great for engineering grade prototypes and end-use parts that should not bend whatsoever.

Stiff

Strong

Smooth

Rigid 4000 will hold its shape under loads of pressure. The 4000 represents the material’s tensile modulus. Rigid 4000 is a high-strength SLA 3D printing material designed for delivering outstanding stiffness and precision.

Ideal Size ≤

14.5 x 14.5 x 18.5 cm

(5.7 x 5.7 x 7.3 in)

Resolution

0.05 - 0.1 millimeters

Colors

White

Economical

Max Size

Flexibility

Strength

Heat Resistance

Economical

Label

Max Size

Label

Flexibility

Label

Strength

Label

Heat Resistance

Label

Specifications

Mechanical Properties

Tensile Modulus

4.1 GPa

ASTM D 638-14

Tensile Modulus

4.1 GPa

ASTM D 638-14

Tensile Strength

69 MPa

ASTM D 638-14

Tensile Strength

69 MPa

ASTM D 638-14

Flexural Strength

105 Mpa

ASTM D 790-15

Flexural Strength

105 Mpa

ASTM D 790-15

Flexural Modulus

3.4 GPa

3.4 GPa

Flexural Modulus

3.4 GPa

3.4 GPa

Elongation at Break

5.3%

ASTM D 638-14

Elongation at Break

5.3%

ASTM D 638-14

IZOD Impact Strength

23 J/m

ASTM D256-10

IZOD Impact Strength

23 J/m

ASTM D256-10

Thermal Properties

Heat Deflection Temperature (1.8MPa)

41 °C

ASTM D 648-16

Heat Deflection Temperature (1.8MPa)

41 °C

ASTM D 648-16

Heat Deflection Temperature (0.45MPa)

48 °C

ASTM D 648-16

Heat Deflection Temperature (0.45MPa)

48 °C

ASTM D 648-16

Thermal Expansion (0-150ºC)

63 μm/m/°C

ASTM E 831-13

Thermal Expansion (0-150ºC)

63 μm/m/°C

ASTM E 831-13

Solvent Compatibility

Acetic Acid 5%

0.8

Acetic Acid 5%

0.8

Acetone

3.3

Acetone

3.3

Isopropyl Alcohol

0.38

Isopropyl Alcohol

0.38

Bleach ~5% NaOCl

0.69

Bleach ~5% NaOCl

0.69

Butyl Acetate

<0.1

Butyl Acetate

<0.1

Diesel Fuel

<0.1

Diesel Fuel

<0.1

Diethyl Glycol Monomethyl Ether

1.4

Diethyl Glycol Monomethyl Ether

1.4

Hydraulic Oil

0.17

Hydraulic Oil

0.17

Skydrol 5

1.1

Skydrol 5

1.1

Hydrogen Peroxide (3%)

0.87

Hydrogen Peroxide (3%)

0.87

Isooctane (aka gasoline)

<0.1

Isooctane (aka gasoline)

<0.1

Mineral Oil (Light)

0.22

Mineral Oil (Light)

0.22

Mineral Oil (Heavy)

0.15

Mineral Oil (Heavy)

0.15

Salt Water (3.5% NaCl)

0.71

Salt Water (3.5% NaCl)

0.71

Sodium Hydroxide Solution (0.025% PH 10)

0.68

Sodium Hydroxide Solution (0.025% PH 10)

0.68

Water

0.7

Water

0.7

Xylene

<0.1

Xylene

<0.1

Material Guide

What feature is most important for your parts?

Most Popular

Best Price

Stiffness

Flexibility

Strength

Great for Bulk Orders

Smoothness

Temperature Resistance

Great for Display

Design Review

Weather Resistance

Impact Resistance

ESD Safe

Recommended Materials:

Material Guide

What feature is most important for your parts?

Most Popular

Best Price

Stiffness

Flexibility

Strength

Great for Bulk Orders

Smoothness

Great for Display

Weather Resistance

Impact Resistance

ESD Safe

Material Guide

What feature is most important for your parts?

Most Popular

Best Price

Stiffness

Flexibility

Strength

Great for Bulk Orders

Smoothness

Great for Display

Weather Resistance

Impact Resistance

ESD Safe

Capabilities

Explore

Applications