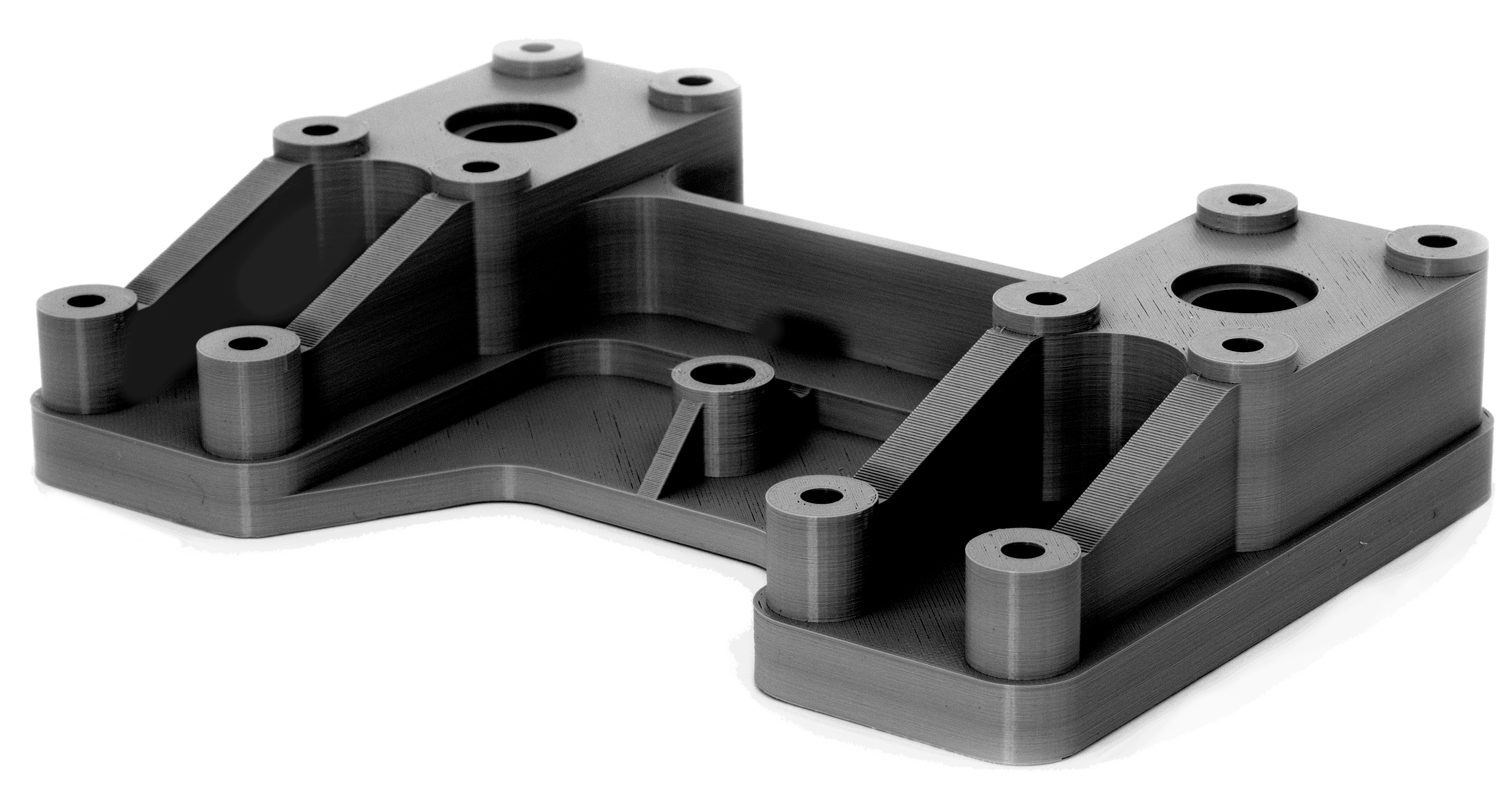

PC (Polycarbonate)

Technology:

Polycarbonate is a high-end material for mechanical applications, offering incredible strength and heat resistance.

Strong

Impact Resistant

PC (Polycarbonate) is an advanced 3D printing material known for its remarkable strength, impact resistance, and thermal stability. Ideal for creating parts that require resilience and longevity, PC excels in applications like automotive and aerospace. With its ability to maintain properties in extreme conditions, PC parts stand the test of time. Choose PC to bring your most ambitious, heavy-duty projects to life.

Ideal Size ≤

256 x 256 x 256 mm

(10 x 10 x 10 in)

Resolution

0.16 - 0.4 mm

Colors

Black

Grey

White